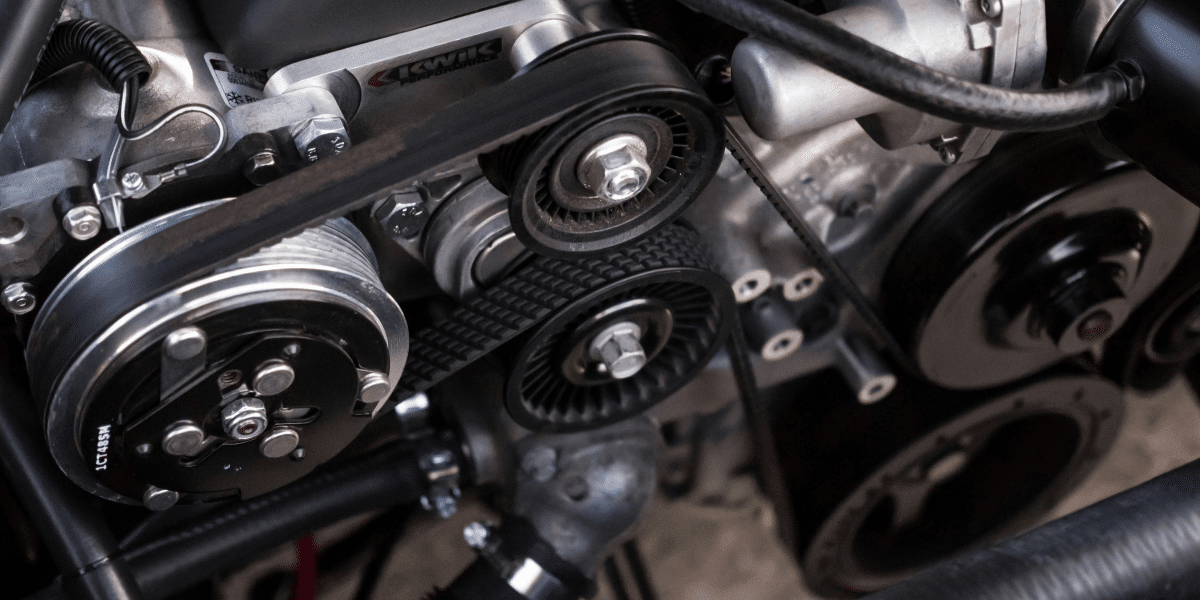

A final drive motor transmits power to the tracks or wheels on heavy equipment and is separate from the primary motor. It can last several years with moderate use, maintenance, and repairs using quality parts. Half of the motor has hydraulic components and utilizes a design with planetary gears.

This relatively small motor does an enormous amount of work so your equipment can run on rough terrain. Whether your equipment uses tracks or wheels, it needs to use power efficiently with extra weight and sharp changes in direction. This motor absorbs feedback and provides most of the torque your equipment needs to function for many years.

Quality replacement parts will keep your engine running while providing maximum torque and smoothly shifting gears. These motors need to connect to the other hydraulic components and fit the overall measurements, exact edge shape, and tooth types of existing gears. Consider the following tips when it’s time to purchase final drive motor replacement parts.

1. The Available Warranty

Consider the amount of wear and tear on your existing motor and the type of work you do with your equipment. You might opt for new parts or refurbished parts, and each will have a different type of warranty. Check the model number, make, brand, and item specifics on each part, any previously replaced parts, and the motor.

Each part will have different warranty conditions based on your motor setup and who installs the parts. You may get a better warranty on certain parts from the same manufacturer or a certified manufacturer of known compatible parts. Note whether or not the warranty depends on installation by either a professional shop or a particular type of accredited shop.

2. Manufacturer Differences

Consider the advice of professionals regarding compatible manufacturers when it comes to performance and a potential warranty. Some parts may come with seemingly comparable warranties, but performance can still vary. Ask about the expected performance considering the age and make of your motor, previously replaced parts, and equipment use.

Always look at the age of your motor and any factory changes that may affect manufacturing processes and variances in finished parts. Your repair technician should be able to inform you about performance consistency regarding certain parts and your equipment model.

3. Compatibility and Specifications

Final drive motors may have one or two sets of planetary gears, four to five ports, different rotation directions, and different bolt counts. Whether you have a short or regular nose motor, check the displacement, reduction ratio, and type of hydraulic connection.

Ask your technician about the compatibility of different gear teeth and any discs your repairs may involve. The edges have a higher chance of looking the same and measuring the same size without working well together. They might have coatings, different cutting or sanding processes affecting metal quality, or varying beveled edges, and may grind or break. These parts deal with extra strain, so don’t skip any questions that may come up regarding durability.

Published by: Martin De Juan